The Quiet Signals Before a Major Operational Failure

Most major operational failures don’t begin with a dramatic event.

They start quietly.

A small work-around.

A missed checklist step.

A production adjustment that “gets us through the shift.”

Individually, none of these trigger alarms. Collectively, they create conditions where risk accumulates unnoticed.

What we see in real operations

In facilities that later experience recalls, injuries, or major downtime, there is almost always a pattern beforehand:

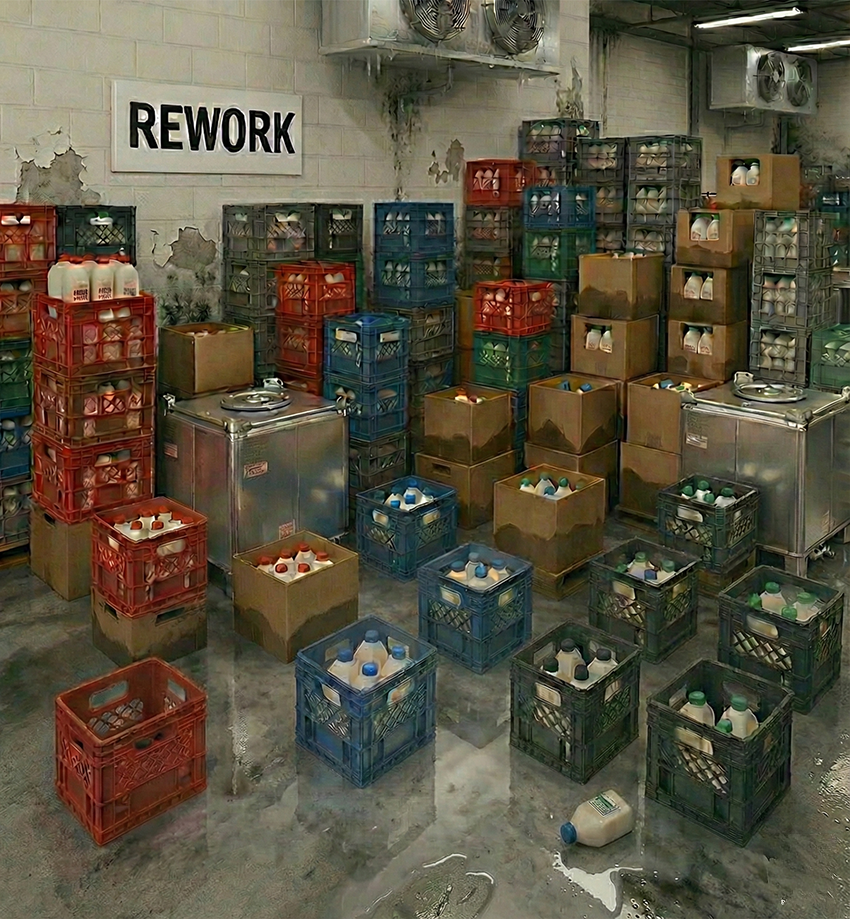

- Minor rework becomes routine

- Near misses stop being reported

- Temporary fixes become permanent

- Variability is accepted as normal

These are not failures of effort. They are failures of visibility.

Teams are busy, production is moving, and nothing feels urgent — until it suddenly is.

Why these signals are easy to miss

Operational leaders are trained to respond to problems, not whispers.

But the most expensive failures rarely announce themselves clearly. They show up as:

- Product loss that’s “within tolerance”

- Holds that clear just fast enough

- Process deviations that don’t quite cross the line

By the time a line is crossed, the groundwork was laid weeks or months earlier.

What strong operations do differently

High-performing operations develop the habit of asking:

- What changed recently?

- What are we tolerating that we didn’t six months ago?

- Where are we relying on individual experience instead of process?

They don’t wait for a failure to justify attention.

They build the discipline to spot early indicators and act while the cost of action is still low.

That habit — the ability to see risk before it becomes visible — is what separates resilient operations from reactive ones.

This type of scenario is explored in depth in our training programs, where participants practice identifying early signals and translating them into practical action.